If you have ever printed 3D designs made for outdoor use, you will most likely have noticed a big difference in performance and durability depending on the different filaments that were used. So to help you decide which option to pick for different outdoor scenarios, let us take a closer look today. Enjoy!

Properties of 3D Filament for Outdoor Use

It is important to understand what properties 3D printer filaments should have when using them outdoors, as they will need to withstand the environment in ways that indoor models generally do not. Below we have listed some of the most important ones.

Weather Resistance

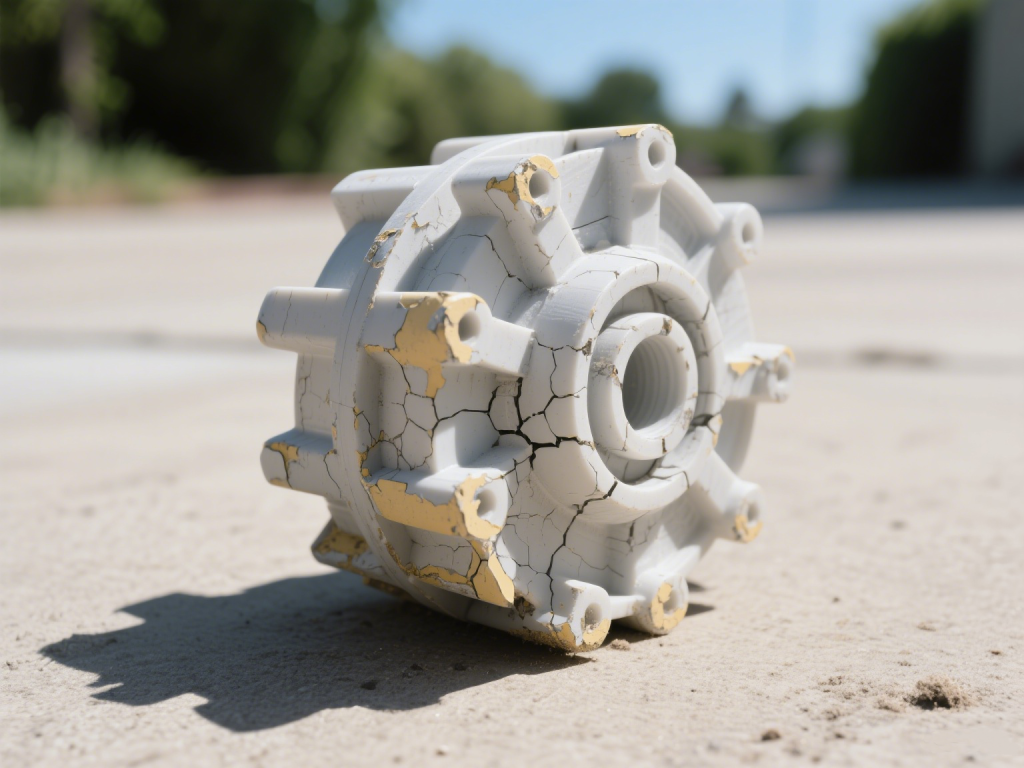

General resistance to the weather in your area is one of the most important factors, so if you live in an area with lots of sunlight, UV-resistant filament should be a priority for your 3D filaments. The same is true for temperature resistance, low or high, so certain filaments hold up better under cold conditions while other filament materials are more ideal for hot conditions. Finally, you’ll want to look at moisture and humidity as well as waterproof capability.

Mechanical Property

Depending on what your 3D print is used for, you might also want to ensure that the filament in question has a decent impact resistance, abrasion resistance or even long-term load-bearing capacity if you are using it to hold certain items in place (like brackets), as this will also narrow down your options of filaments.

Chemical Stability

And finally, some outdoor environments make it crucial for you to consider corrosion resistance and oxidation resistance, especially if you live near the ocean, where moisture, salt and pollutants from the sea can degrade your model, or harsher environments where the air quality and UV radiation might oxidize your models earlier than intended.

Comparison of Filaments Suitable for Outdoor Use

Below we have provided an overview of the main characteristics for each of the following 5 filaments, ASA, PETG, PC, Nylon and TPU. As well as some recommended application scenarios of these materials.

| Property | ASA | PETG | PC | Nylon | TPU |

| UV Resistance | Excellent | Good | Moderate | Poor | Moderate |

| Temp Resistance | High (80-100°C) | Moderate (70-85°C) | Very High (110-135°C) | Moderate (80-100°C) | Moderate (50-80°C) |

| Water Resistance | Good | Excellent | Good | Poor (absorbs) | Excellent |

| Impact Resistance | High | Moderate | Very High | High | Very High (flexible) |

| Abrasion Resistance | Good | Moderate | Excellent | Good | Excellent |

| Load-Bearing | Good | Moderate | Excellent (rigid) | Good (flexible) | Poor (too soft) |

| Chemical Stability | Excellent (resists corrosion) | Good (resists moisture) | Excellent (resists oils, chemicals) | Moderate (absorbs moisture) | Good (resists oils, solvents) |

| Best For | Outdoor signs, automotive parts, fixtures | Waterproof containers, garden tools | High-strength structural parts, helmets | Functional gears, hinges | Seals, gaskets, flexible parts |

ASA Filament

As you can see in the table above, ASA filament is generally the best filament for outdoor use, as it works well for most scenarios. ASA performs more stably in extreme climates. It has excellent UV resistance and is not prone to fading or becoming brittle even after long-term exposure to sunlight, and Good water resistance and excellent chemical resistance.

But its printing difficulty is relatively high, requiring a heated bed and a closed printing cabin. It is prone to curling edges. The cost of ASA filament is also relatively high, around $30/KG.

PETG Filament

Next up, we have PETG 3D printer filament which is not as temperature resistant, but is a great water safe 3D printer filament, making it a good option in climates where it often rains, as well as for garden utilities such as planter boxes or similar. The PETG UV resistance is also decent, but a little poorer than ASA. If your budget is not sufficient to choose ASA, or if your print is not used in extreme weather, PETG will be a more cost-effective option. And PETG’s threshold for printing skill is also lower than that of ASA.

Click here to buy PETG filament bundle.

PC Filament

The highest performing material for high temperature tolerance is polycarbonate filament and it can be a major determinant in specific situations. Generally speaking, this high temp 3D printer filament also does an excellent job of enduring most other elements as well and is an excellent choice for a wide variety of builds.

Nylon Filament

Nylon filament can be a great option for functional parts that are not directly exposed to water, as the water absorption property is a main downside of nylon as a material in many cases. It is considered quite a decent heat resistant 3D printer filament as well, making it applicable for a number of uses. There are also reinforced versions of nylon on the market that are chosen by outdoor enthusiasts.

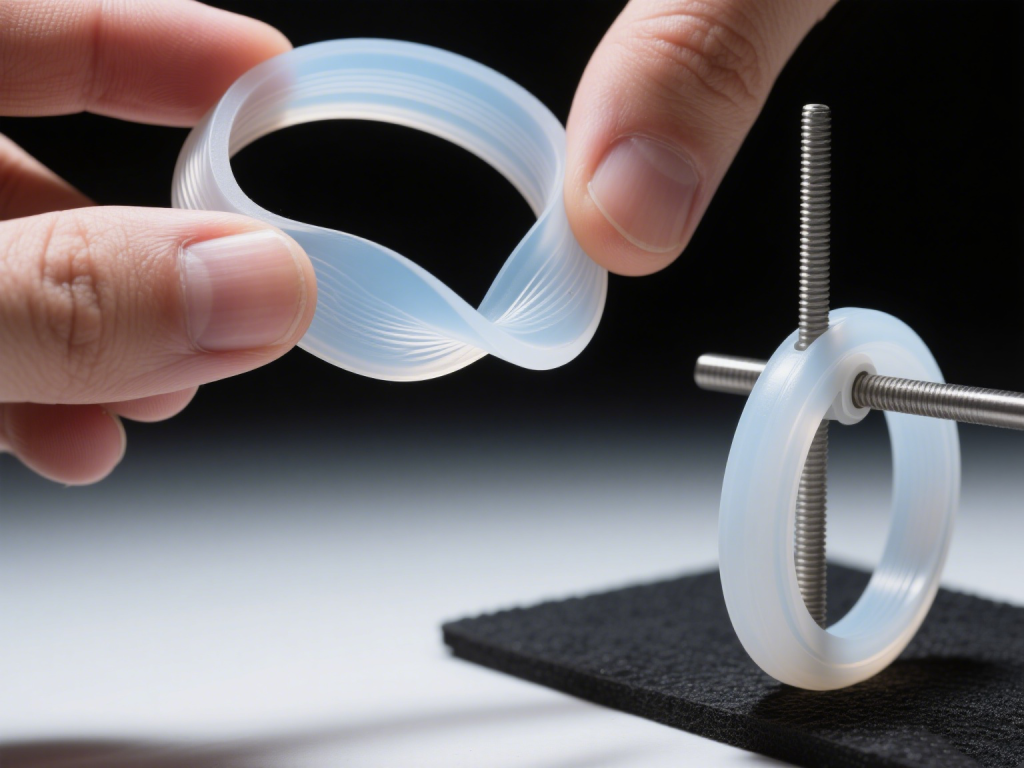

TPU Filament

And finally, TPU filament is quite poor in terms of temperature resistance, and also not a great option for load-bearing projects. However even the lower point of 50°C is more than enough for outdoor use in most parts of the world, and the impact resistance property of TPU filaments is the best out of the filaments we have covered, making it great for parts or items needing that extra strength, and some flexible components (like outdoor water bottle sealing rings and garden faucet sealing rings) that can’t be printed by ASA, PETG and others strong 3d printer filament.

How to Improve Prints’ Outdoor Durability?

Now that we have categorized the properties of different 3D printing filaments for outdoor use according to the main factors playing a role in durability, it is worth noting that we also have the option of enhancing the durability even further with post-processing or when designing our models.

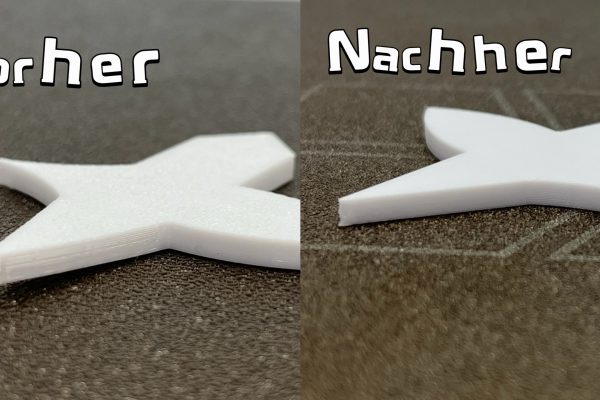

Post-Processing

Once your design is finished in the printer, you can further improve durability by spraying UV protective paint on your models in order to further increase their resistance to sunlight, and avoid them losing strength or fading as rapidly. In general this can be applied to all types of materials, but each type of filament might require a different product, so be sure to research what works for ASA or TPU for instance.

The same goes for waterproof coating that can make the models absorb less water, although this coating might need to be reapplied in extreme cases. You can also chemically smooth your prints in order to seal the layer lines, while also reducing the penetration of moisture, thus making your models last longer.

Optimization Design

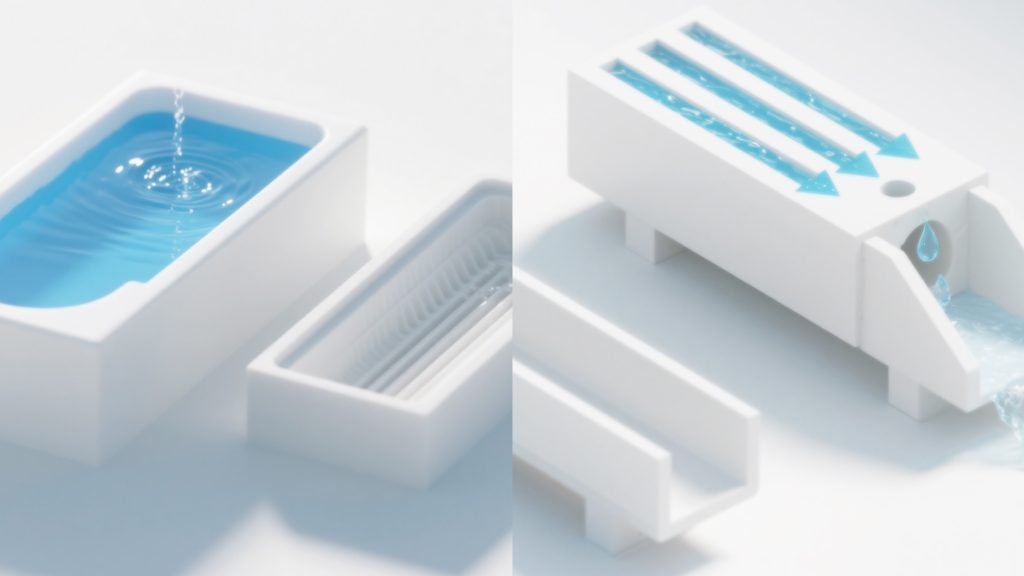

No matter which filament you use on your 3D printer, you’ll always be able to choose to design your models with more material to make them stronger. For example, you may want to make the walls thicker so you’ll get more strength and resistance, and the models won’t degrade so easily as the extra layers will be slower to degrade over time naturally.

You should also consider avoiding water accumulation structures, as some designs might have pockets that catch water and let it sit, so design your models according to the environment in order to optimize and provide a longer lifespan.

Conclusion

All in all, we have many fantastic options for printing 3D models designed to be used outdoors, that can last a long time while also maintaining their structural integrity and beautiful surfaces. And by taking a little extra time to plan ahead and make sure you use the best possible filament, perform post-processing if needed and optimize the design to fit the environment, your designs can last for years without any issue. We hope you enjoyed this article and learned something. Thanks for now!