When you wish to 3D print your new designs, you are met with many different options of printing filament to choose from. You could go for ABS or PLA as they are quite common and affordable, but depending on your needs and how the model will be used, there are some interesting alternatives.

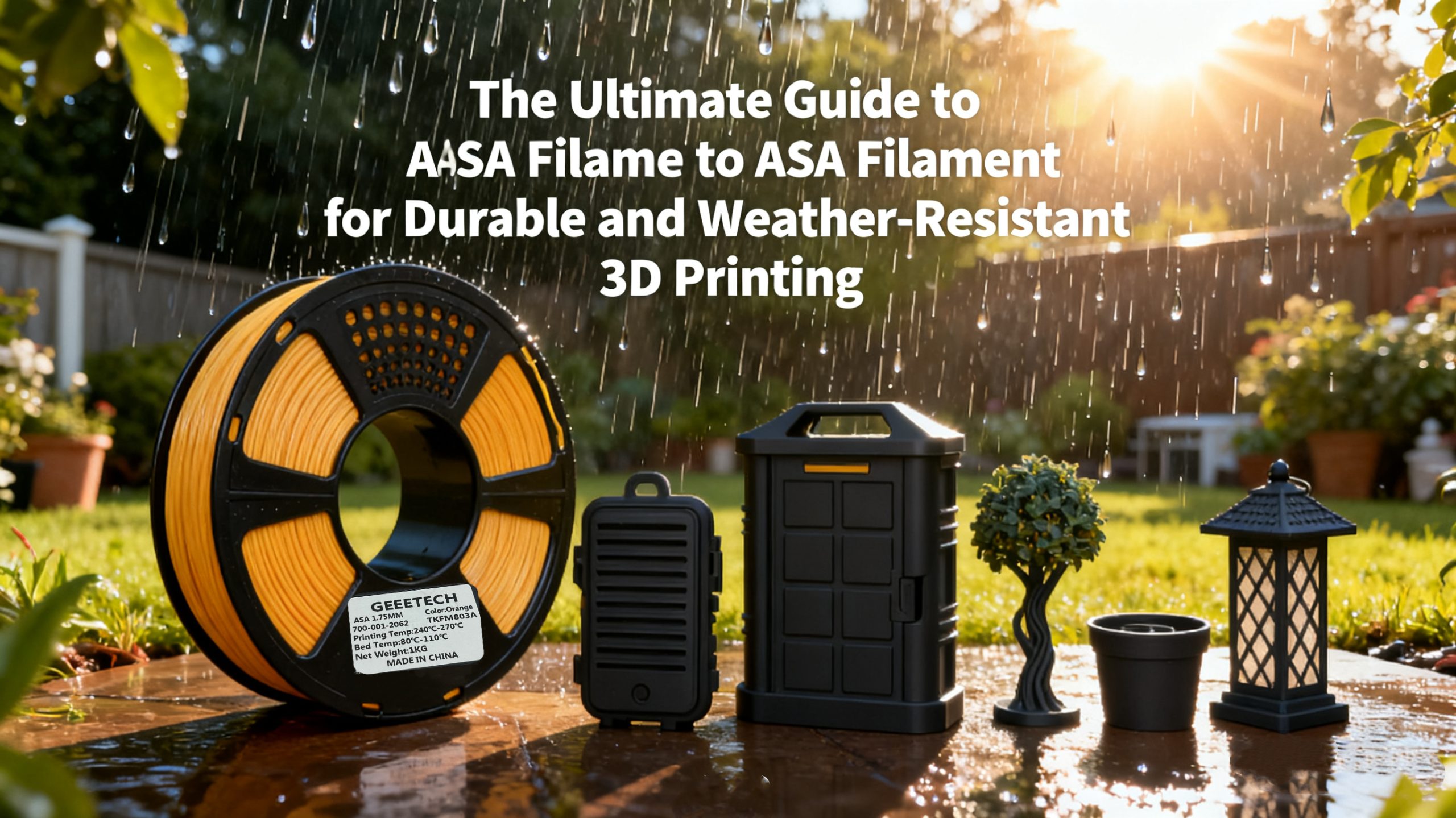

One of these is called ASA, which is short for acrylonitrile styrene acrylate, and this filament is amazing for use outside as well as for projects where you need a solid and robust material that can withstand a number of different environments and last a long time. So let us take a closer look at the ASA filament.

What Is ASA Filament

Many people consider ASA plastic filament to be an upgrade over ABS, as both materials share many of the same properties. Where they differ lies in the difference between the acrylate used in ASA and the butadiene used in ABS. The difference is particularly important when it comes to prints being exposed to UV light, such as from the sun, since butadiene is not really resistant to these rays.

ASA, on the other hand, is developed to be a highly resistant material, thanks to the graft polymerization process using acrylate rubber. So when it comes to UV radiation, it is tough in terms of handling weathering from the environment, and even chemical reactions. In short, ASA filament is a better option for most outdoor projects and a good replacement for prints that normally call for using ABS.

Properties of ASA in 3D Printing

We’ve briefly touched on the overall ASA filament properties when used for 3D prints. Let us take a closer look at the specifics with our detailed table, providing an easy overview, making it easy to figure out the best bed temperature when printing ASA, for instance.

| Property | Details |

| Print Temperature | 240–270 °C |

| Bed Temperature | 80–110 °C |

| Tensile Strength | ~35–37 MPa |

| UV Resistance | Excellent, one of ASA’s main strengths |

| Weather Resistance | Excellent, ideal for outdoor use |

| Heat Resistance | High, better than PLA and ABS |

| Warping | Moderate, similar to ABS, enclosure recommended |

| Print Difficulty | Medium/High |

| Surface Finish | Matte, good layer adhesion |

Advantages and Disadvantages of ASA Filament

Given the properties seen above, we can discuss the pros and cons of using ASA filament in 3D models, and more easily figure out what applications and specific designs are best suited for this material.

Advantages

The main advantage over similar types, such as ABS, or even PLA and PETG, is that ASA has an exceptional resistance towards UV radiation and weathering. This not only impacts the discoloring which often happens with other materials, but it also means the overall strength of your models will stay in much better shape for a longer time.

And speaking of mechanical strength, ASA is great when looking at numbers for impact resistance and tensile strength, due to the shared similarities to ABS. You can easily use ASA in both your prototype designs as well as functional projects, without worrying whether it will last.

ASA also has a great glass transition temperature score of around 100°C, which means the material can withstand environments or exposure to high temperatures. In fact, it even outscores PLA which is known to be a great choice in scenarios where this matters. As a result, ASA will not deform when inside a car on a hot summers day for instance, unlike many other materials.

There’s also something to mention when it comes to chemical resistance: ASA can resist degradation from many of the most typical chemicals in our natural world. Both acids and alkalis are no match for ASA, with oils and greases also having a tough time with the filament. But you can still easily sand, paint or even glue ASA materials, making post-processing easy.

Disadvantages

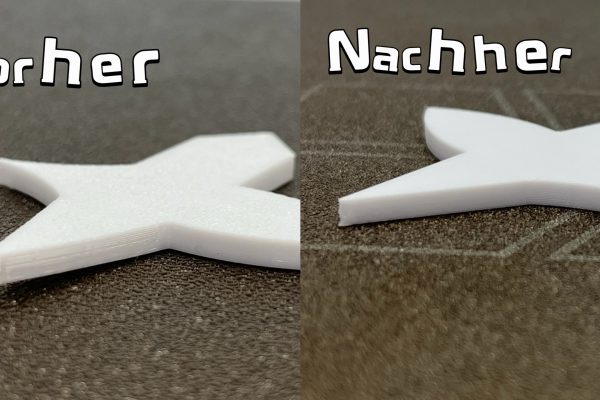

There are two main disadvantages when it comes to ASA in 3D printing applications. The first one is warping and shrinking, since the individual components together make for a material that can more easily warp or separate layers, thanks to the high temperature during printing with ASA. Experienced 3D printing hobbyists can remedy this by using a well-heated print bed and improve further by enclosing the printer.

The other potential issue is the ASA filament fumes produced when printing. ASA releases what is called styrene fumes, that not only smell strongly but can also be irritating for some people. It is recommended to print with good ventilation or filtration systems when using ASA, or at least print in a garage or shed and only briefly be present while the process takes place.

Tips of Printing ASA Filament

There are quite a few different manufacturers producing ASA 3D filament, making it difficult to provide instructions that will work well for all. Therefore, we have used Geeetech ASA 3D printer filament as our baseline, where we have spent time tweaking the values during printing to find a set of perfect ASA print settings:

| Property | Best Value |

| Nozzle temperature | 240-270 ℃ |

| Bed temperature | 80-110 ℃ |

| Cooling fan speed | 40-50% |

| Initial layer cooling speed | 0% |

| Build plate adhesion | Brim & Skirt |

ASA vs ABS

Many people tend to be indecisive between ASA and ABS, therefore we think it is fitting to briefly discuss the differences between ASA and ABS in 3D printing. We’ve also written a more extensive blogpost on this particular topic, which you can find here: ASA vs. ABS: Which Is the Ultimate Value Champion in 3D Printing.

If you wish to just get the quick explanation, ASA is better for UV resistance. ABS will often turn brittle and lose color when outside, while ASA will stay stable. They both share similar properties when it comes to mechanical strength. Use ABS for indoor, functional parts where cost is a key factor. Choose ASA for any part that will be exposed to sunlight, rain, or variable outdoor conditions.

Neither ABS nor ASA is super easy to print with, especially when looking at something like PLA as an alternative. However, if you have the necessary setup both ABS and ASA can produce great results without much trouble. ABS filaments are slightly better in this aspect, as they do not warp nearly as much in general. ABS can also be a bit cheaper.

Applications

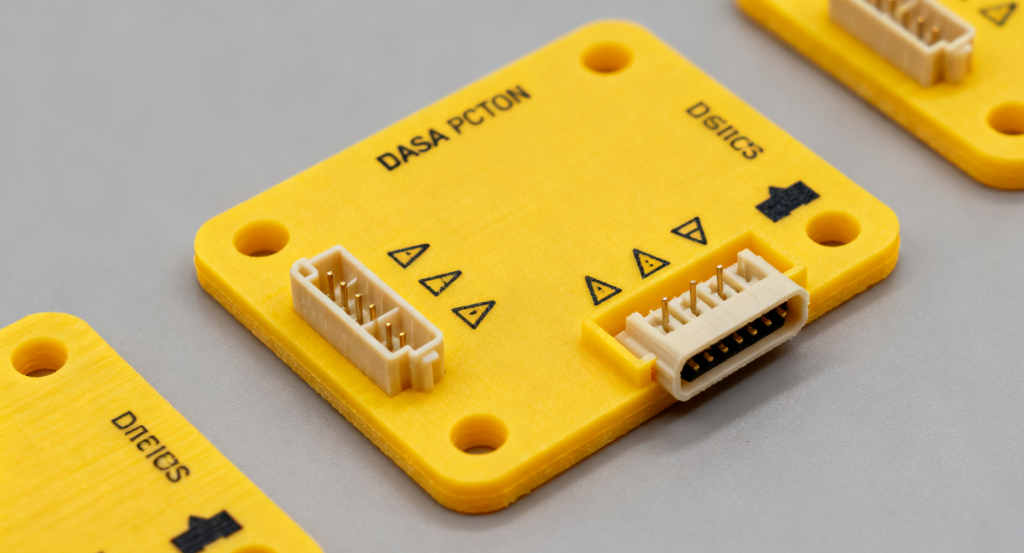

There are many different areas, hobbies and industries where ASA is a great material. Below we’ve provided a list of examples based on three different categories, but there are of course many others. And when all is said and done, it will ultimately depend on your own preferences and needs for the model and application.

Outdoor Applications

- Planters

- Irrigation parts

- Tool handles

- Exterior trim

- License plate holders

- Custom side mirrors

- Electrical enclosures

- Outdoor sensor casings

- Mounting brackets for solar lights

- Drone bodies

- GoPro mounts

- Outdoor signage

High Mechanical Strength and Heat Resistance Applications

- Functional prototypes

- Dashboard components

- Engine bay brackets

- Air ducts

- Router enclosures

- Raspberry Pi cases

- Power tool housings

- Custom jigs and fixtures

- Machine parts

- End-use functional components

Long-Lasting Required Applications

- Architectural models

- Custom tools and jigs

- Replacement appliance parts

- Laboratory equipment housings

- Educational models and kits

- Museum displays and replicas

- Outdoor furniture components

- Industrial parts subject to wear

Conclusion

Whether you’re an engineer, a hobbyist, or a product designer, learning ASA can provide a world of opportunities to build practical and weather-resistant 3D printed models. When looking at ABS vs ASA filament, both are powerful and versatile materials, but ASA additionally provides great weather resistance.